DETECTION OF DETRIMENTAL INTERMETALLIC PHASES

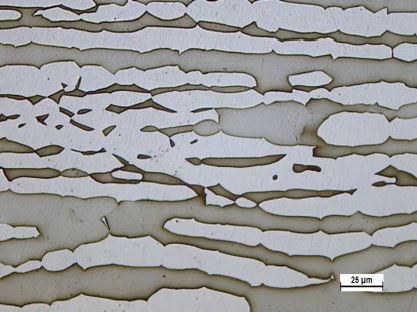

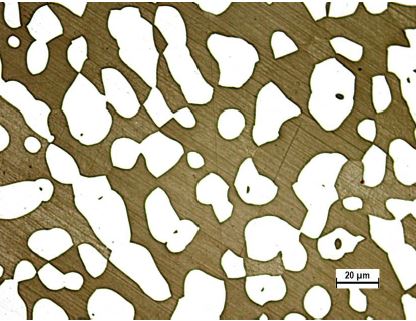

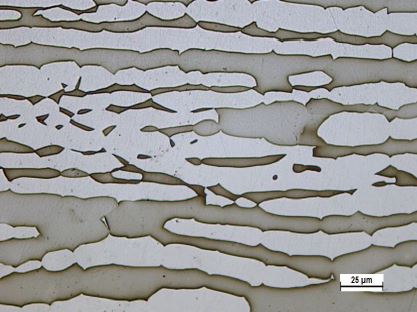

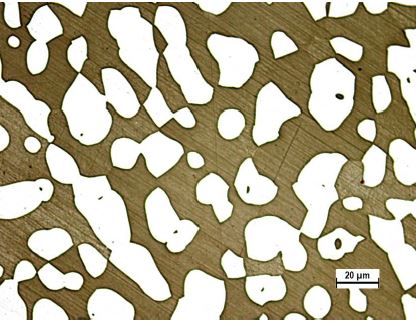

Sodium hydroxide etch test is often used as a screening test to detect detrimental intermetallic phases and allows to classify the etch structures.

Another test method consists in ferric chloride corrosion test, through procedures that are similar to those used for pitting and crevice corrosion. Test piece is immersed in the solution at constant temperature generally for 24 hours. After that the specimen is washed, rinsed and brushed to remove corrosion products. Then, weigh loss is registered and the corrosion rate , in milligrams per square decimeter per day (mdd), is calculated in accordance to total surface area and time.

Also Charpy impact test can be used as a method of detecting the precipitation of detrimental intermetallic phases in duplex stainless steels. For this particular scope the standard ASTM 923-14 provides a table about the applicability and acceptance criteria with regard to the different materials and their condition (base metal, heat-affected zone and weld metal).

TEST METHODS

- ASTM A 923 – Method A

- ASTM A 923 – Method B

- ASTM A 923 – Method C

PHENOMENON DESCRIPTION

Duplex stainless steels are susceptible to the formation of intermetallic compounds during exposures in the temperature range from approximately 320 to 955°C. The presence of these phases is a function of composition and thermal or thermomechanical history of each piece and has detrimental effects to toughness and corrosion resistance. Different test methods can be adopted in order to detect the presence of detrimental intermetallic phases.

MORE INFORMATION

Ask a question or request a quote fulfilling the mask below

or call us at (+39) 0523 881 900

Required fields marked with *

YOU NEED ANOTHER TEST?

SIDERTEST

is ACCREDITED FOR A WIDE RANGE OF TESTS