Disbonding Test

The disbonding test refers to bimetallic stainless alloy/steel plate and is commonly carried out according to ASTM G146. A cylindrical specimen is subjected to high pressure hydrogen environment at elevated temperature for a specific period of time.

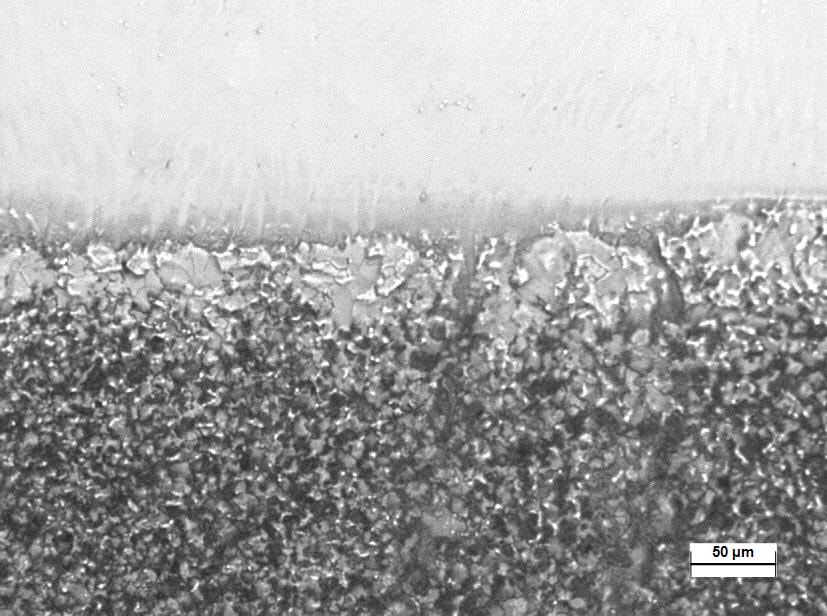

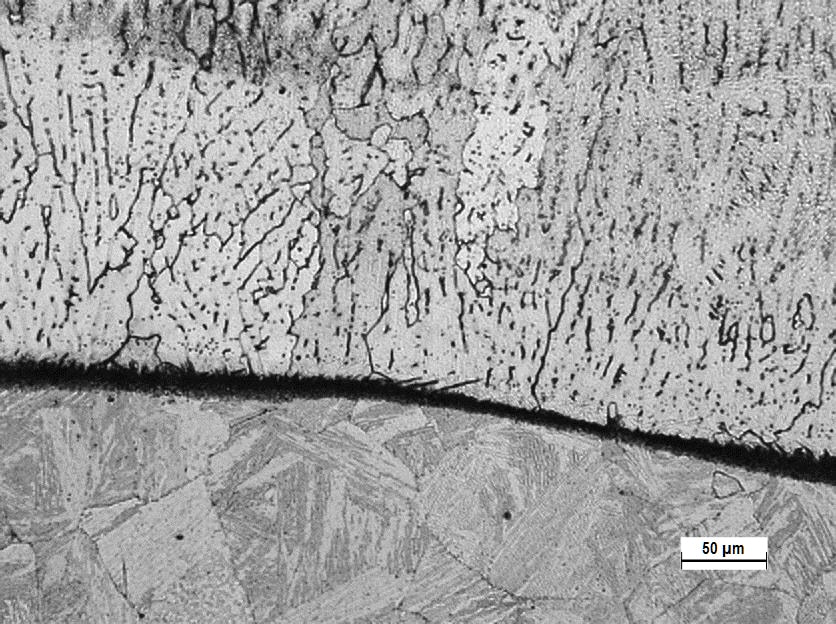

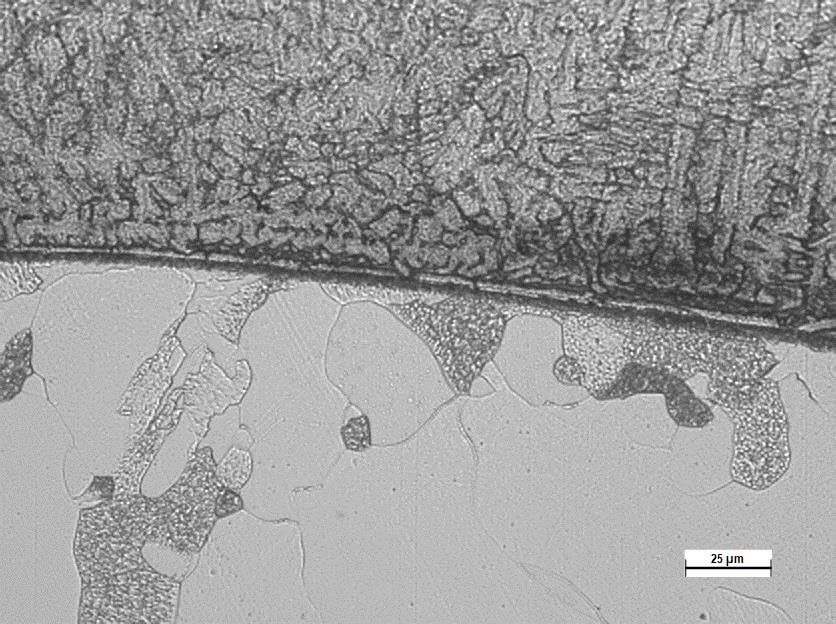

Following the exposure to these hydrogen charging conditions, the specimen is cooled to room temperature and evalued by ultrasonic technique and metallographic examination in order to detect disbonding cracks and detachments caused by the hydrogen in the stainless steel overlays.

TEST METHODS

- ASTM G 146

PHENOMENOM DESCRIPTION

The test is purposed to investigate the effects of the phenomenon of Hydrogen Induced Disbonding, also known as HID, and involves in particular the Oil & Gas.

In fact the practice is intended to simulate the refinery service conditions, characterized by high pressure, high temperature and presence of hydrogen, that could induce cracks, bulges and blistering on the cladding steel.

MORE INFORMATION

Ask a question or request a quote fulfilling the mask below

or call us at (+39) 0523 881 900

Required fields marked with *

YOU NEED ANOTHER TEST?

SIDERTEST

is ACCREDITED FOR A WIDE RANGE OF TESTS