TEST FOR WELDING QUALIFICATIONS

Sider Test performs all the destructive and non-destructive tests required for the qualification of welding procedures (according to WPS and WPQR), welders, brazers and welding operators. Our personnel can provide the compilation of WPS (Welding Procedure Specification) and WPQR (Welding Procedure Qualification Report) and help the customer to get ISO3834 and EN1090 certifications.

What do WPS and WPQR mean?

What do WPS and WPQR mean?

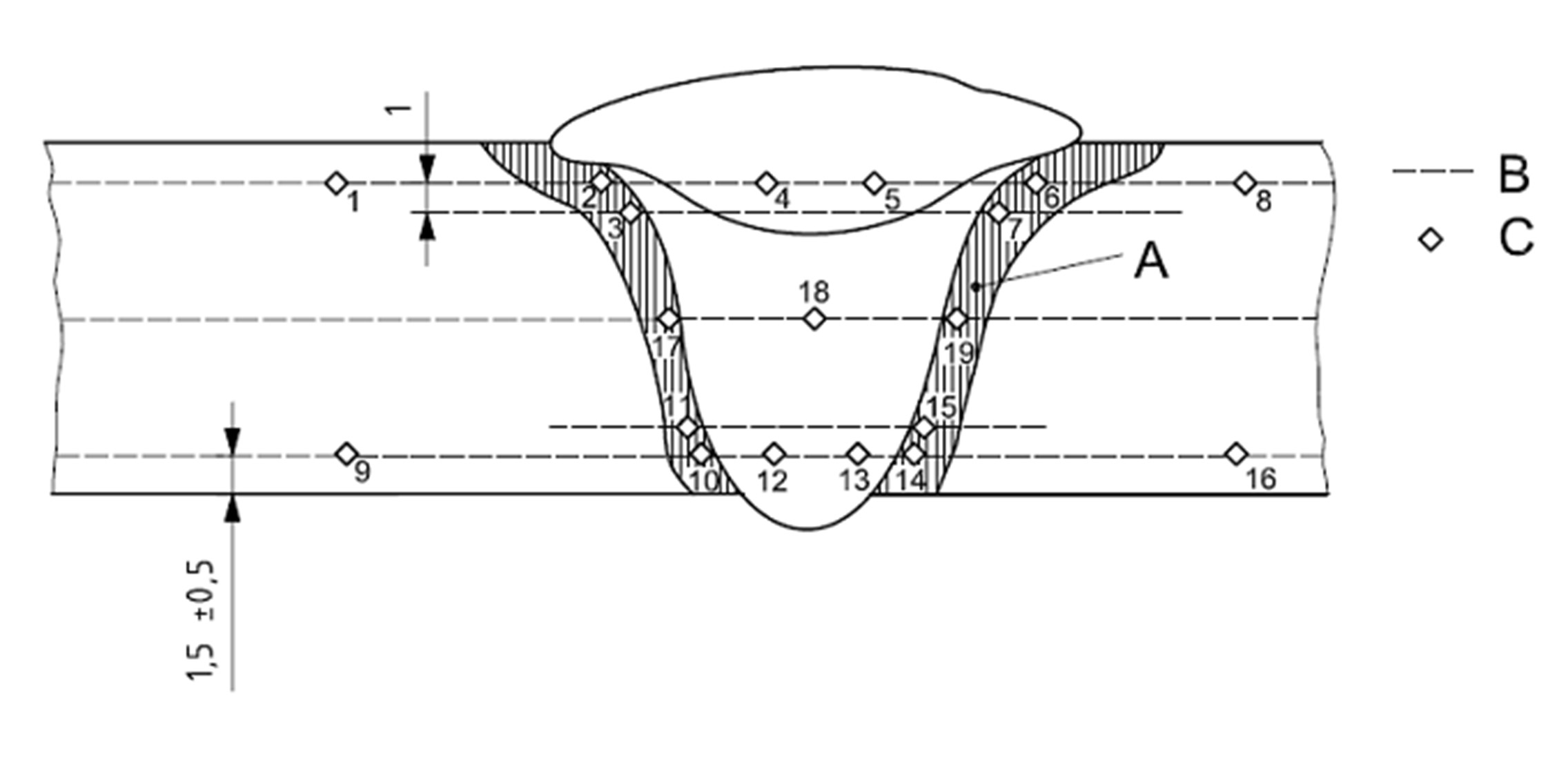

A WPS (Welding Procedure Specification) is a document reporting the parameters of the welding with refers to a qualification welded joint (a tube or sheet metal)

The variables include the indication of the welding technique, base material and filler metal, the specification of the shielding gas type and the description of further technical parameters (e.g. position, preheat temperature and many others).

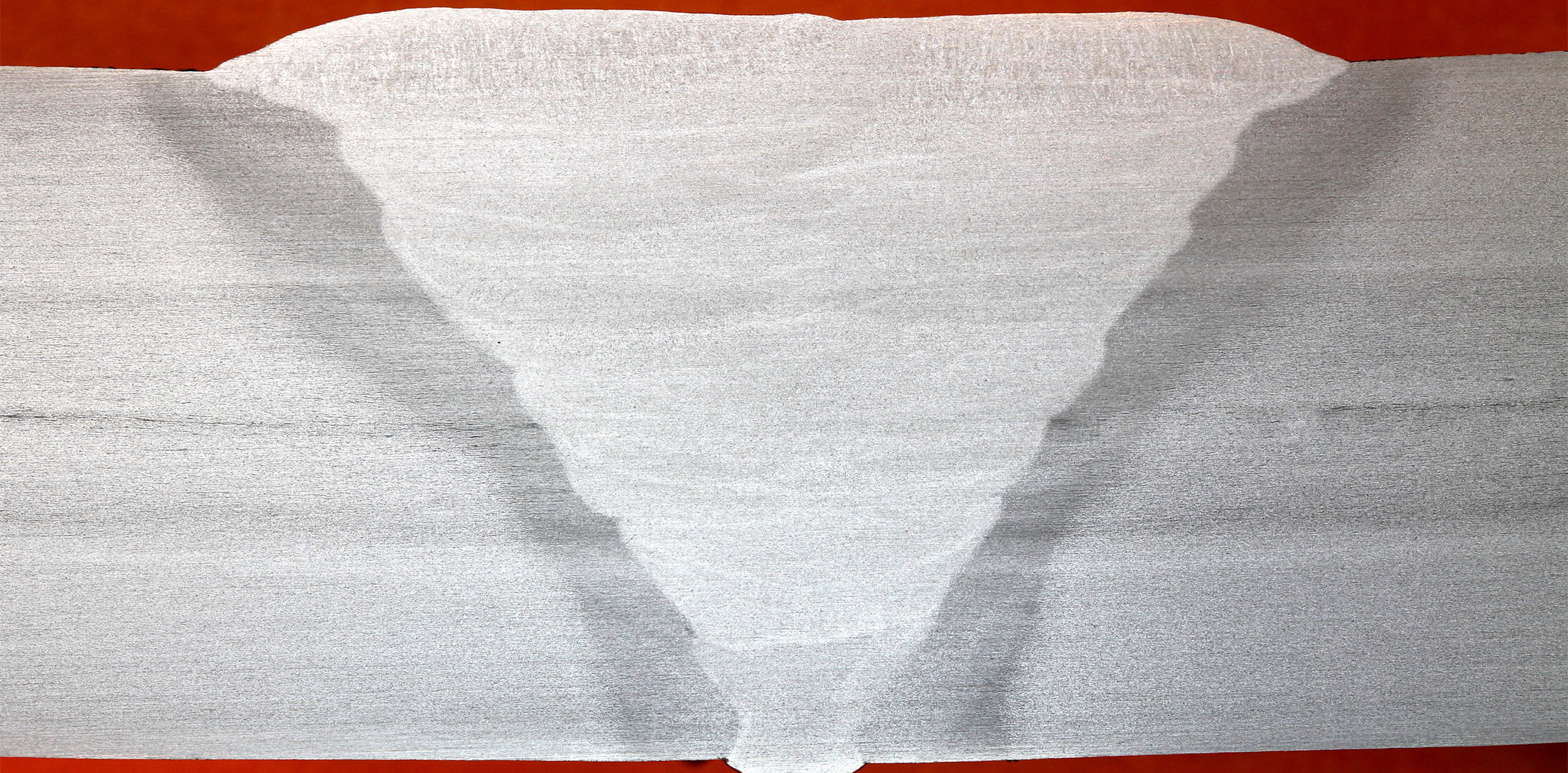

The joint, welded in accordance with the parameters described in the WPS, is subjected to destructive and non-destructive tests. This is necessary in order to compile a document called WPQR (Welding Procedure Qualification Report), that reports the tests results and qualify the company or the welder for the execution of the welding procedure as described.

Certification of the Welding Quality System

The ISO 3834 standard defines the quality requirements for welding of metallic materials. It is a fundamental reference to manage all the welding processes and represents an ideal integration to ISO 9001

The EN1090 standard came into force on the 1st July 2015. It is required for producers of structural steel or aluminium works. It is a mandatory requirement for the CE marking of the products.

Sider Test performs the laboratory tests required to obtain both the certifications.

Qualification of Welders and Welding Operators

The technical skill and performance of the welding personnel (welders or welding operators, depending on the technique adopted: manual either automatic) is certified by their qualification. The qualification process requires the production of a weld sample in accordance with the WPS contents and the execution of the laboratory tests as established by the standard or code. The qualification of the welder is valid for a period of two years. After the expiration, the qualification must be renewed.

Welding Qualification Process: a Strategic Factor for Successful Companies

Companies with qualificated welding procedures and figures can reach and mantain high levels of quality and efficiency. They demonstrate to pursue the safeguard of the final user and the possibility of becoming providers of international market leaders.

Welding qualifications are recalled as compulsory requirements by several international directives and regulations (e.g. PED Directive 97/23EC on pressure equipment) and are included among the compulsory requirements described by many important companies’ technical specifications and terms of contract (as engineering companies, EPC contractors, Oil&Gas companies and institutes).

MORE INFORMATION

Ask a question or request a quote fulfilling the mask below

or call us at (+39) 0523 881 900

Required fields marked with *

YOU NEED ANOTHER TEST?

SIDERTEST

is ACCREDITED FOR A WIDE RANGE OF TESTS