SSC (SULPHIDE STRESS CRACKING)

Test standards describe many different procedures to simulate and evaluate the reaction of the material to the double effect of mechanical strenght and corrosion attack. Various H2S solutions and chloride content solutions may be used to simulate sour environments.

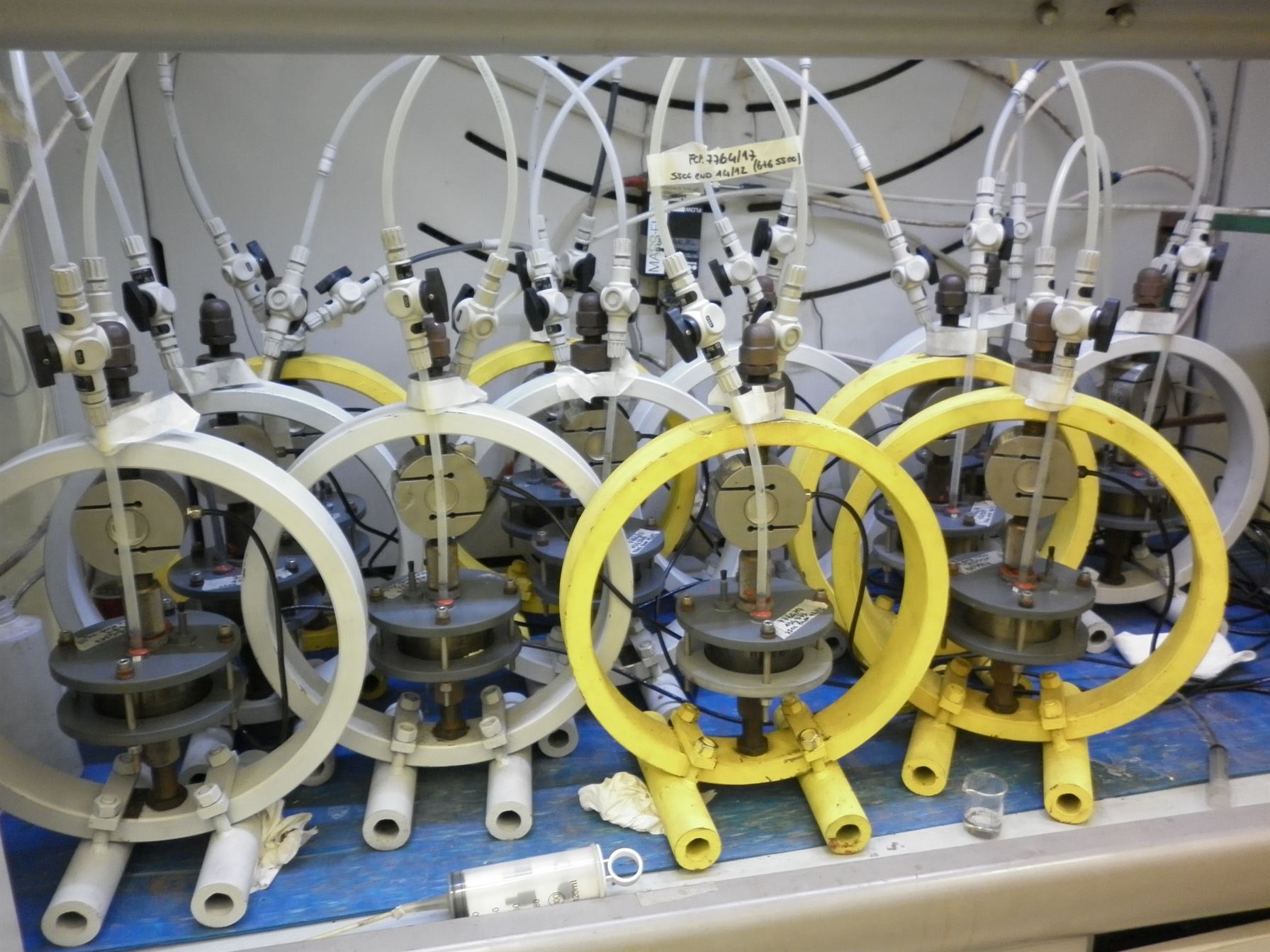

One of the test methods sets forth the procedure for loading a tensile test specimen placed in a vessel containing the corrosion solution a particular stress level. “ Proof-ring ” is one of the practical and precise instrument to evaluate the resistance to SSC this way.

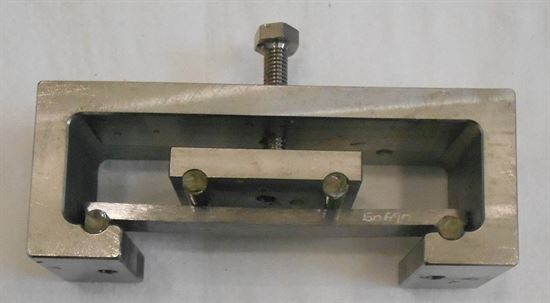

Another method involves deflecting rectangular specimens in a series by applying a different bending stress through particular instruments, as the four point bending fixture. According to the data obtained by testing multiple test specimens at varying deflections, a critical critical stress factor (Sc)is calculated. Test specimens are immersed in acid solution for 720 hours, then removed, cleaned and inspected in order to determine any crack presence.

PHENOMENON DESCRIPTION

- EFC 16 3° Edizione

- ANSI NACE TM0177- Metodo A + ASTM G49

- ANSI/NACE TM0177 Metodo C C-ring

- EFC 16 3° Edizione Metodo B + ISO 7539-2

- ANSI/NACE TM0177 Metodo B + ASTM G39

- EFC 16 3° Edizione Metodo C + ASTM G38

- ANSI/NACE TM0177 Metodo C + ASTM G38

- EFC 16 3° Edizione Metodo C + ISO 7539-5

- NACE TM0316

- ANSI/NACE TM0177 Metodo D

PHENOMENON DESCRIPTION

The test addresses the resistance of metals to cracking failure under the combined action of tensile stress and corrosion in aqueous environments conatining hydrogen sulfide (H2S). This phenomenon is generally termed sulfide stress cracking (SSC) when operating at room temperature and stress corrosion cracking (SCC) when operating at higher temperatures.

SSC of metals exposed to oilfield environments containing H2S was recognized as a materials failure problem by 1952. Laboratory data and field experience have demonstrated that even extrememly low concentrations of H2S may be sufficient to lead to SSC failure of susceptible materials.

MORE INFORMATION

Ask a question or request a quote fulfilling the mask below

or call us at (+39) 0523 881 900

Required fields marked with *

YOU NEED ANOTHER TEST?

SIDERTEST

is ACCREDITED FOR A WIDE RANGE OF TESTS