HIC (HYDROGEN INDUCED CRACKING)

NACE TM 0284 Standard was originally prepared in 1984 to provide a standard set of conditions for consistent evaluation of pipelines steels and for comparison of test results from different laboratories. More recently, the concern for HIC damage in steel fittings and flanges used in pipelines and pressure vessels has led to their inclusion in the 2011 revision of this standard. Therefore, the scope of this standard now includes the testing of steels furnished in the form of pipes, plates, fittings, and flanges for use in fabricating pipelines and pressure vessels.

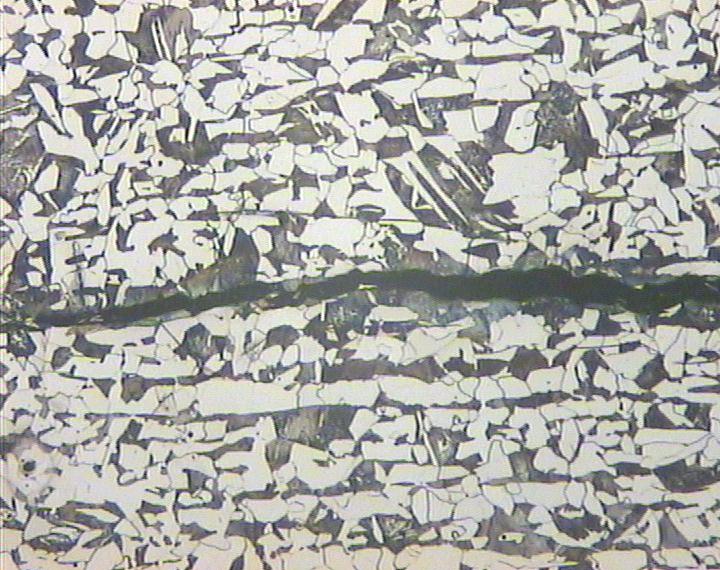

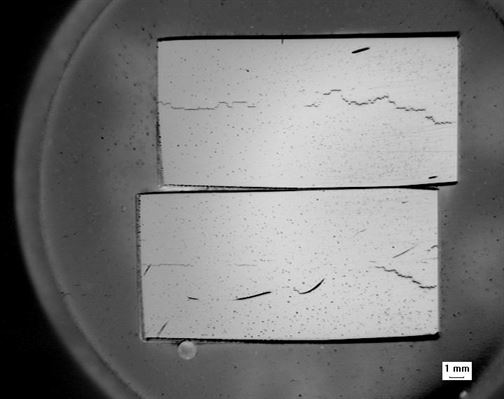

The test consist of exposing unstressed test specimens to one of the two standard test solution -either Solution A, a sodium chloride (NaCl), acetic acid (CH3COOH) solution saturated with H2S at ambient temperature and pressure, or solution B, a synthetic seawater solution saturated with H2S at ambient temperature and pressure. After a specified time the test specimens shall be removed and evaluated. After testing, each specimen must be sectioned and each section must be polished metallographically and etched, so that cracks can be distinguished. The observed cracks are measured and their dimensions (lenght and thickness) are reported in order to calculate the following ratios: CSR (Crack Sensitivity Ratio), CLR (Crack Lenght Ratio) e CTR (Crack Thickness Ratio). These ratios are calculated and reported for each section and the average for each test specimen.

TEST METHODS

- NACE TM 0284

PHENOMENON DESCRIPTION

Absorption of hydrogen generated by corrosion of steel in a wet hydrogen sulfide (H2S) environment can have several effects that depend on the properties of the steel, the characteristics of the environment and other variables. One adverse effect observed in pipeline and pressure vessel steels is the development of cracks along the rolling direction of the steel. cracks on one plane tend to link up with the cracks on adjacent planes to form steps across the thickness. The cracks can reduce the effective wall thickness until the pipe or pressure vessel becomes overstressed and ruptures. Cracking is sometimes accompanied by surface blistering.

The terms stepwise stepwise cracking, hydrogen pressure cracking, blister cracking or hydrogen-induced stepwise crackingof this type, but are now considered obsolete. NACE International has adopted the term hydrogen-induced cracking HIC.

Hydrogen blistering has been recognized since the 1940s as a problem in vessel handling sour products. It was not until much later, however, that HIC started to be investigated and gained recognition as a potential problem in pipelines as a result of pipeline failures experienced in the early 1970s.

MORE INFORMATION

Ask a question or request a quote fulfilling the mask below

or call us at (+39) 0523 881 900

Required fields marked with *

YOU NEED ANOTHER TEST?

SIDERTEST

is ACCREDITED FOR A WIDE RANGE OF TESTS