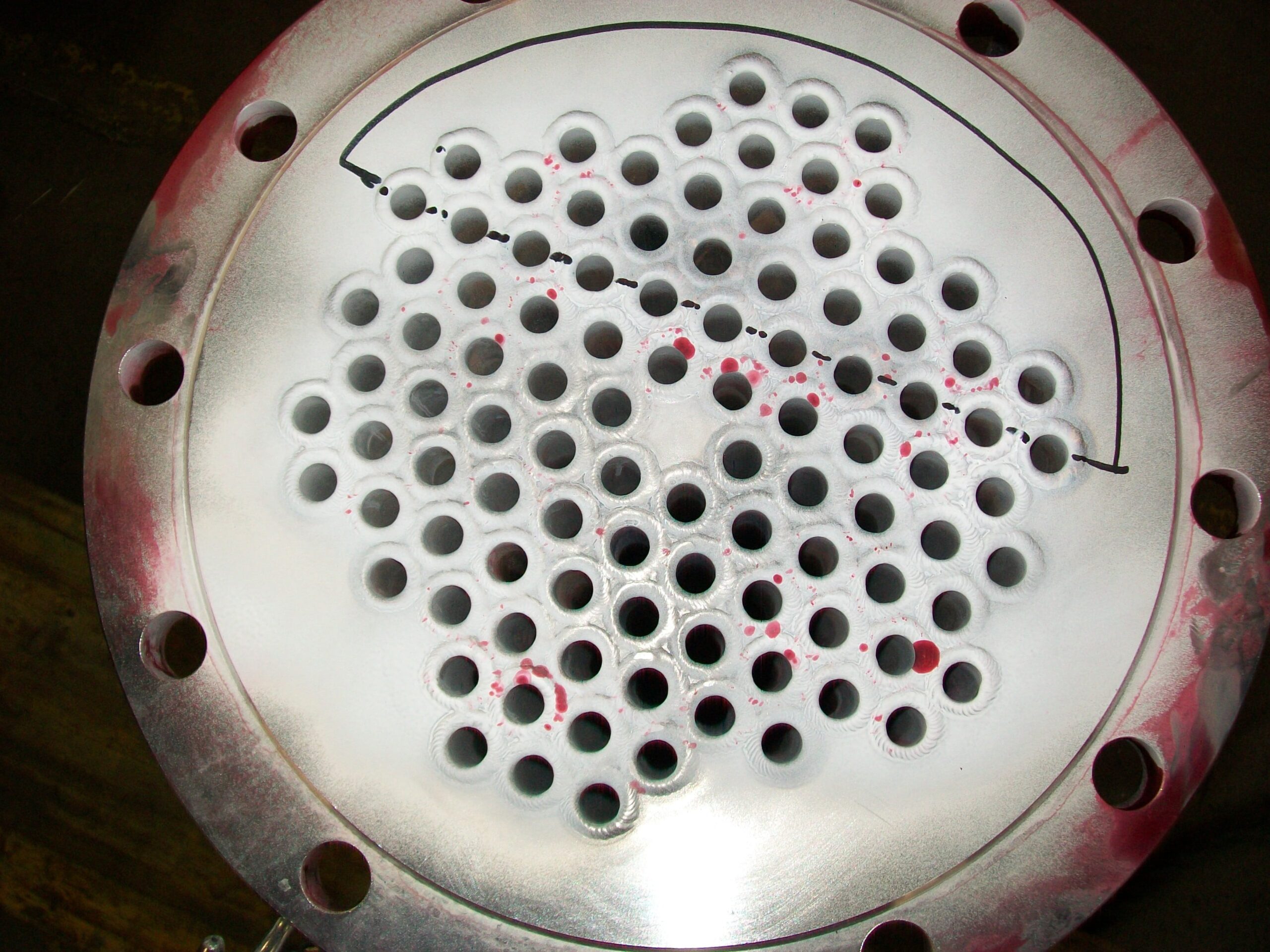

PENETRANT TEST

Liquid penetrant testing can detect and locate superficial defects, like discontinuities, cracks and lacks of fusion. After the cleaning and preparation of the surfaces of the product being inspected, red visible or fluorescent dye penetrant is applied. The capillary action cause the penetrant to seep into the superficial defects. Then the excess liquid is removed from the surface and a developer, a powder or a liquid, is applied in order to draw the penetrant and make it visible showing the defects’ positions. Fluorescent liquids are highlighted by the ultraviolet light.

TEST METHODS

- ASME BPVC.V Art. 6 – 24

- ISO 3452-1

MORE INFORMATION

Ask a question or request a quote fulfilling the mask below

or call us at (+39) 0523 881 900

Required fields marked with *

YOU NEED ANOTHER TEST?

SIDERTEST

is ACCREDITED FOR A WIDE RANGE OF TESTS