METALLOGRAPHIC EXAMINATIONS

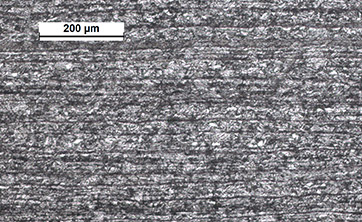

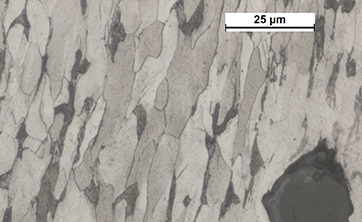

BANDIFICATION OF THE MICROSTRUCTURE

Microscopic examination to evaluate the isotropy or anisotropy of the material and determine “oriented” or “layered” microstructures that affect the mechanical properties of the material

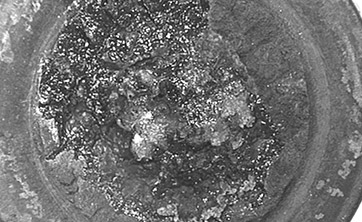

MACROGRAPHIC EXAMINATION

Observation with the naked eye or at low magnification to check the quality of the weld and identify any defects and to highlight the arrangement of the fibers

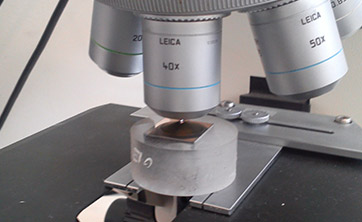

MICROGRAPHIC EXAMINATION

To observe at high magnification the metallographic structure, the configuration of the grains, the distribution of the phases or the possible presence of defects

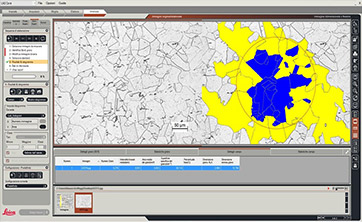

VOLUME FRACTION AND PERCENTAGE OF THE PHASES

To calculate with an adequate degree of statistical precision the volume fraction of compounds and phases present in the material examined and to detect the ferrite content present in steels

NON METALLIC INCLUSIONS

To analyze, evaluate and classify the presence of different non-metallic inclusions such as sulphides, oxides and silicates which differ in size, shape, concentration, distribution and chemical composition

AVERAGE GRAIN SIZE

The determination of the austenitic / ferritic grain size is performed (BECHET – BEAUJARD / KOHN by oxidation, MC – QUAID EHN according to ASTM E 112 and corresponding)

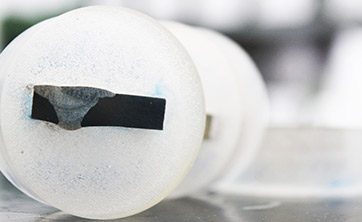

METALLOGRAPHIC REPLICAS

Non-destructive method carried out with qualified personnel to analyze the metallographic structure of an object without compromising its integrity

DETRIMENTAL INTERMETALLIC PHASES

Specimens attached with sodium hydroxide which allows to highlight the presence of intermetallic phases and to classify their structure with observation under the microscope

MORE INFORMATION

Ask a question or request a quote fulfilling the mask below

or call us at (+39) 0523 881 900