YOUR STRATEGIC PARTNER IN MATERIAL TESTING

MECHANICAL WORKSHOP WITH 4.0 TECHNOLOGY

ECO-SUSTAINABLE DEVELOPMENT

TIMELINESS & EFFICIENCY

FOR MORE THAN 30 YEARS

LAST NEWS

ABOUT SIDER TEST LAB

TIMELINESS & EFFICIENCY

FOR MORE THAN 30 YEARS

For this reason, the Management of SIDER TEST has chosen to accredit most of the test methods supplied according to EN ISO 17025. The accreditation includes mechanical tests, chemical analysis, metallographic examinations, corrosion tests, NDT and much more.

TEST US!

SIDER TEST

LAST NEWS

ABOUT SIDER TEST LAB

CLIENTS WORLDWIDE

OPERATING HEADQUARTERS

QUALIFIED EMPLOYEES

ACCREDITED TEST

SAMPLES PRODUCED IN 24 HOURS

TEST PERFORMED IN A YEAR

ONLY 4 DAYS SINCE SAMPLE RECEIPT TO RESULTS

1° DAY

2° DAY

3° DAY

4° DAY

document control,

registration and storage.

test definition;

contractual finalization

with assignment of the order

to the operational department.

tracking, checks,

reports and data, storage.

customer feedback and assistance

1° DAY

document control,

registration and storage.

2° DAY

contractual finalization with assignment

of the order to the operational.

3° DAY

tracking, checks,

reports and data, storage.

4° DAY

customer feedback and assistance

MATERIAL TESTING SERVICES

Mechanical tests

The mechanical tests allow to characterize

the behavior of the material

when subjected to mechanical stresses

that can be continuous

or instantaneous, diffuse or punctual,

at room temperature,

hot or cold

Chemical analyses

The analysis of the chemical composition

allows through different techniques

to identify and quantify the elements

present in the material.

Analyzes can be conducted

in the laboratory or in the field,

where the components are installed

Metallographic examinations

In metallographic analyzes,

the experience and competence

of the laboratory technician

are of fundamental importance

in order to deepen information

on the structure of the material

through magnification techniques

various metallographic attacks

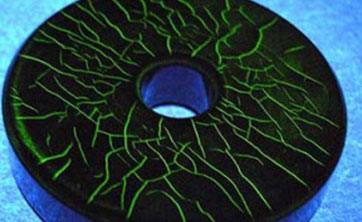

Non destructive checks

The non-destructive tests allow

to analyze the quality of the material

without the need to alter it

or to take any sample.

It is therefore possible to locate

and evaluate any defects

in the material without

compromising its integrity

and functionality

corrosion in sulfidric acid

Corrosion and stress corrosion tests

in solutions with hydrogen sulphide

evaluate the behavior of

materials in conditions of use

typical of the Oil&Gas sector.

The standards for these tests

refer mainly to the NACE

regulatory body

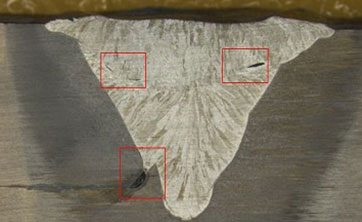

Disbonding test

Carbon steel specimens coated

with stainless steel layers

are tested under the environmental

conditions of the refineries,

characterized by the presence

of hydrogen in a gaseous state.

Any detachments induced

by hydrogen penetration

are evaluated

Failure analysis

Through careful investigations,

the causes of breakage,

damage or malfunction of a metal

component are determined.

Sometimes the tests also allow

to identify useful solutions

to avoid the repetition

of the detrimental phenomenon

Corrosions

The reactions resulting from these tests

are the result of electrochemical phenomena

that allow conclusions to be drawn

on the resistance of the material

to wear and exposure to certain agents

and service conditions

determined by the reference standards

Simulated heat treatments

Portions of the material,

subsequently tested,

are subjected through the use

of ovens dedicated to tempering,

stress relieving, annealing,

normalization, tempering,

hardening from aging and solubilization

and step cooling treatments

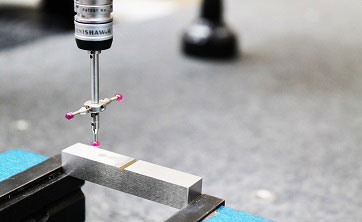

Dimensional checks

Through highly qualified personnel and extensive technical equipment that includes a CMM coordinate measuring machine, dimensional measurements and checks are carried out, as well as carrying out internal quality checks on the dimensions of the specimens built

Personalized tests

Based on the specific needs of the customer, customized tests and inspections are carried out. This is a service that may require the development of special equipment and tools specifically built to simulate the operating conditions of components and products

Construction of specimens

The laboratory is equipped with a large and modern workshop for the mechanical processing necessary for the preparation and processing of the specimens. The robotic systems allow speed and quality. These services are also offered to customers with their own internal laboratory who request them

MORE INFORMATION

Ask a question or request a quote fulfilling the mask below

or call us at (+39) 0523 881 900