SSC TEST – SSCC TEST

(SULPHIDE STRESS CORROSION CRACKING)

SSC Test measures stress corrosion cracking in hydrogen sulphide (H2S) solutions.

Contact between hydrogen sulphide (H2S) an steel conduct to crack formation following a mechanism called Sulphide Stress Cracking (SSC) or Sulphide Stress Corrosion Cracking (SSCC). Both acronyms are synonymous and are referred to crack developed perpendicularly to surfaces made in contact with hydrogen sulphide (H2S) in presence of a mechanical stress. This combination lead to a particular environmental corrosion phenomena called tenso corrosion.

TEST METHODS

- EFC 16 3° Edizione

- ANSI NACE TM0177- Metodo A + ASTM G49

- ANSI/NACE TM0177 Metodo C C-ring

- EFC 16 3° Edizione Metodo B + ISO 7539-2

- ANSI/NACE TM0177 Metodo B + ASTM G39

- EFC 16 3° Edizione Metodo C + ASTM G38

- ANSI/NACE TM0177 Metodo C + ASTM G38

- EFC 16 3° Edizione Metodo C + ISO 7539-5

- NACE TM0316

- ANSI/NACE TM0177 Metodo D

SSC Test – SSCC Test – Sulphide Stress Corrosion Cracking

NACE TM0177, TM0316, EFC16: the most common standards

SSC resistance can be studied with different methodologies codified through the decades by NACE and EFC. The most used reference standards for ssc test are NACE TM0177 NACE TM0316 and EFC 16. Test solution used have different composition depending on the test method chosen but are mainly made with sodium chloride, acetic acid and/or sodium acetate. These reagents simulate the water environment that item will come into contact during service. Solution are then saturated with hydrogen sulphide (H2S) and then test samples are soaked after applying a desired stress with a geometry variable from method to method.

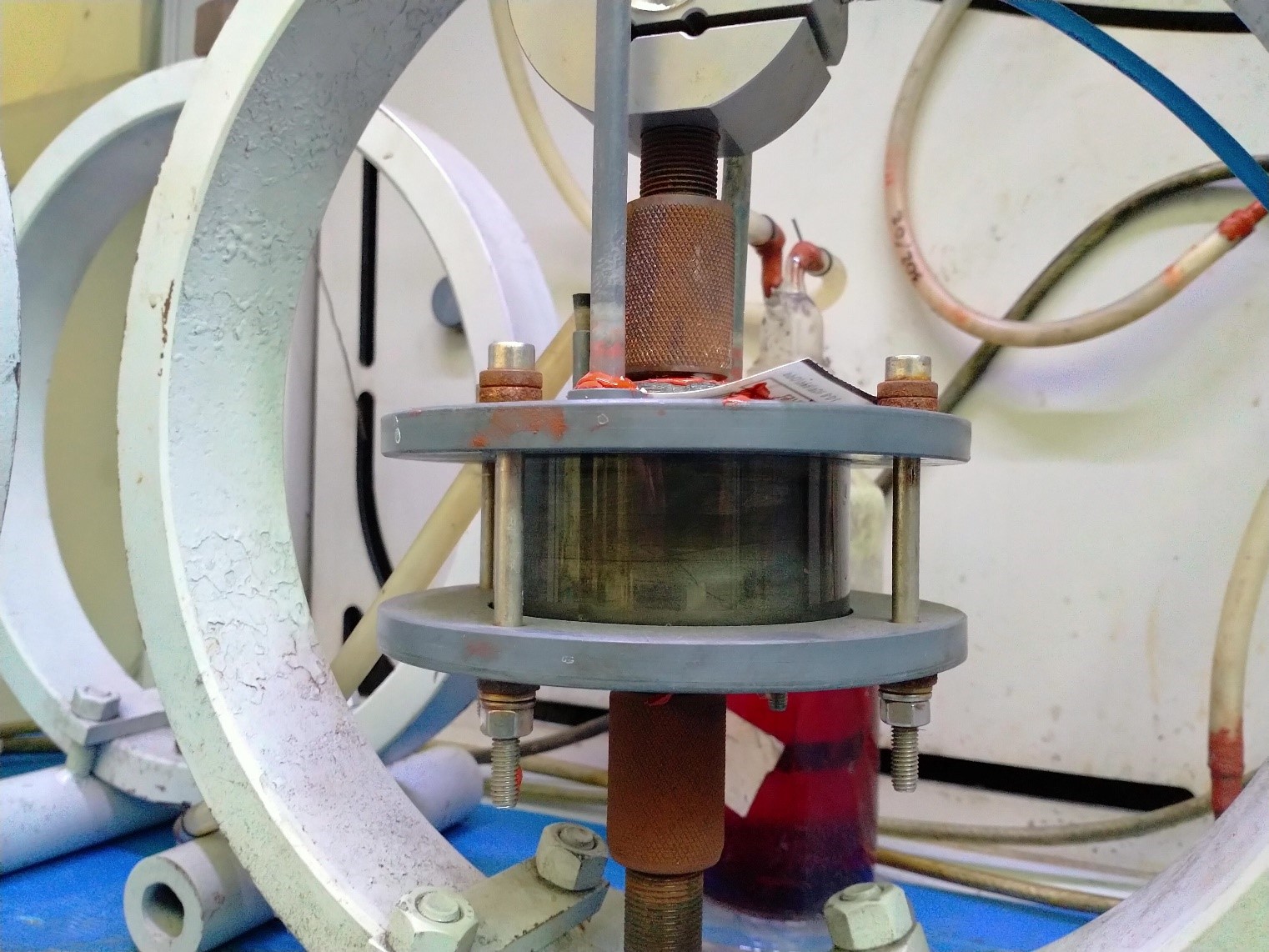

The most common one is called Four Point Bending (FPB) and it is required mainly according to ssc test NACE TM0316, NACE TM0177 + ASTM G39 or EFC 16 Method B. It consist in a parallelepiped tensioned with four contact points where the main stressed region is localized between the two central roller. Otherwise, when it is necessary apply a stress with a particular direction, Sulphide Stress Cracking (SSC) or Sulphide Stress Corrosion Cracking (SSCC) is tested with a proof ring arrangement. Required frequently according to NACE TM0177 o EFC 16 Method A, it remember a tensile test sample with the stress applied in a single direction and immersed in the corrosion environment. The third way to test hydrogen sulphide (H2S) is the so called C-Ring. This test is particularly indicated in testing pipes. Test sample is a section with a sector of 120-150° removed. It remember the shape of letter C and it is drilled orthogonally and tension using a stainless steel threaded bar. The main stress is concentered in the location opposite to the removed one.

Tensocorrosion:

Stress Critical Factor measurement

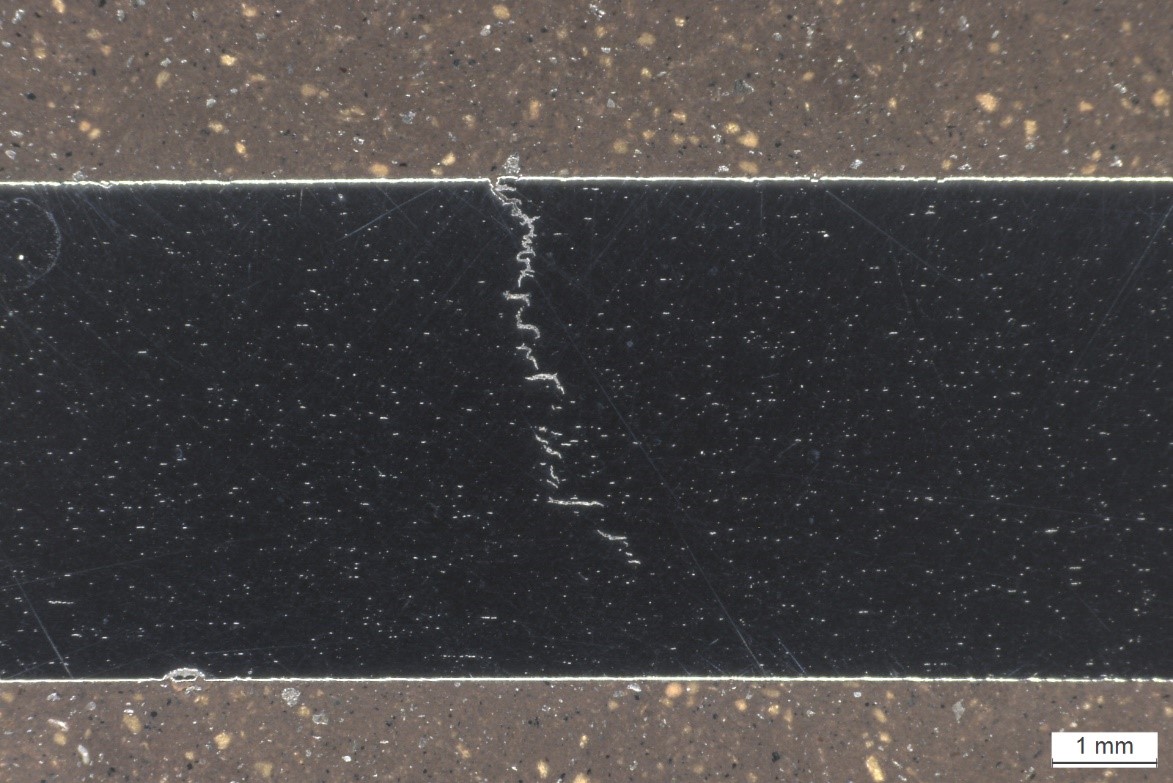

There are some cases in which is necessary to measure Stress Critical Factor (Sc) that represent the deflection beyond which 50% of tensioned samples will fail and manifest Sulphide Stress Cracking (SSC) o Sulphide Stress Corrosion Cracking (SSCC). This parameter is measured according to NACE TM0177 Method B. It shall not be confused with Four Point Bending (FPB), the test sample present two drilled holes in the middle and it is stressed using three contact points. The methods use a statistical approach in order to measure Sc and need a robust statistical base composed by multiple test samples in order to calculate a robust parameter. Last one is Double cantilever, regulated by NACE TM0177 and EFC 16 method D. It consist in a parallelepiped shaped test sample with a slot and a fatigue precrack. Sample is tensioned using a wedge with a fixed geometry and in this case, the calculated parameter is the critical stress intensity factor or KISSC. Test is inserted in the studies of fracture mechanics and directly correlated with the environment containing hydrogen sulphide (H2S) able to initiate Sulphide Stress Cracking (SSC) or Sulphide Stress Corrosion Cracking (SSCC). In any case an independently form method chosen the test duration is 720 hours. At the end the stressed area is analyzed in order to determine the presence/absence of cracks.

SSC tensocorrosion

Sour service corrosion

CRA e sour service corrosion

This corrosion mechanism arises from the combination of an applied stress and a saturated corrosive environment saturated with hydrogen sulphide (H2S). This corrosion mechanism is called Sulphide Stress Cracking (SSC) o Sulphide Stress Corrosion Cracking (SSCC) when it regards carbon and low alloyed steels. If the involved alloys are stainless or duplex steels or CRA (corrosion resistant alloys) it is called Stress Corrosion Cracking (SCC). Its dangerousness is recognized since the early ‘50s due to several incident occurred in the oil and gas industry and related to hydrogen sulphide (H2S) contact with steel. Laboratories experiments and matured experience on the field showed that even extremely low concentration of hydrogen sulphide (H2S) are able to start the phenomenon and lead to catastrophic consequences. Material selection specifications such as MR0175/ISO15156 have been developed in order to facilitate the adoption of specific criteria that guarantee resistance to hydrogen sulphide (H2S) and the phenomena mentioned above for carbon, low alloyed steels and CRA.

Sour service corrosion

MORE INFORMATION

Ask a question or request a quote fulfilling the mask below

or call us at (+39) 0523 881 900

Required fields marked with *

YOU NEED ANOTHER TEST?

SIDERTEST

is ACCREDITED FOR A WIDE RANGE OF TESTS