SOHIC (STRESS ORIENTED HYDROGEN INDUCED CRACKING)

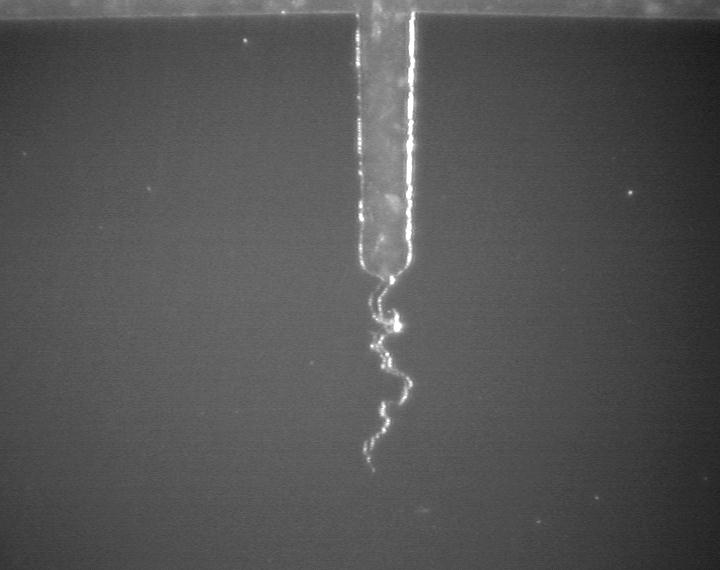

NACE Standards TM 0177 and TM 0284 are extensively utilized in the evaluation and qualification of steels for determination of resistance to SSC and HIC, respectively. However, neither of these test methods deals directly with the specific mechanism and mode of cracking inherent to SOHIC. NACE Standard TM 0103 covers specifically the testing of carbon steels for the evaluation of their susceptibility to cracking in aqueous hydrogen sulfide (H2S) environments by the phenomenon known as SOHIC. The standard provide the procedures to evaluate the resistance of the material to through-thickness cracking in the presence of a tensile stress and a stress concentrator used to initiate cracking. It requires to use different types of test fixtures, one of these is the “ double beam “. After 168 hours specimens are removed from the test vessel, cleaned, sectioned and visually examined. The extent of SOHIC propagation is determined by examination of the of the four polished sections from the two stressed beam specimens. The total lenght of SOHIC crack is measured and the lenghts of both continuous and discontinuous crack propagation are recorded.

TEST METHODS

- NACE TM 0177 Metodo A

- NACE TM 0103

PHENOMENON DESCRIPTION

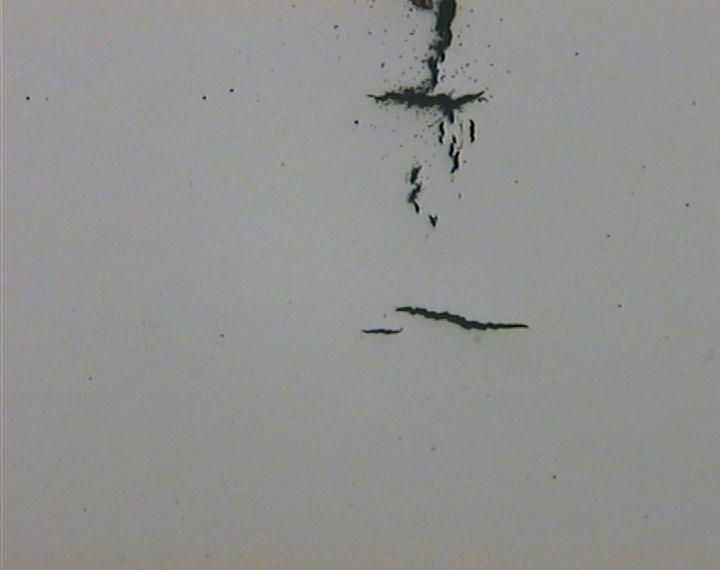

Carbon steel plates employed in welded pressure vessels may be susceptible to one or more forms of environmental cracking when exposed to wet H2S service conditions. One of these is called stress-oriented hydrogen induced cracking (SOHIC).Cracking observed in steel equipment resulting from SOHIC appears to be mechanistically related to HIC because it involves the formation of small blisters in the steel and the development of interconnecting cracks that link adjacent blisters on different planes in the steel, however, in SOHIC, the orientation of these blisters is much different. The presence of an applied or residual tensile stress in the steel (typically adjacent to the weld heat-affected zone) produces stacked arrays of these blisters and the interconnecting cracking is oriented in the through-thickness direction. Susceptibility to HIC has been generally shown to be gratest in high-sulfur steels and decrease with decreasing sulfur content of the steel. By comparison, in severe hydrogen-charging environments, SOHIC susceptibility can increase as the sulfur content in the steel decreases from the level commonly found in the conventional plate steels until very low levels of sulfur are reached, when susceptibility to SOHIC can decrease. However, at very low sulfur contents, several other variables in the steel may play a role in determining SOHIC as well. These include the presence of ferrite-pearlite banding, carbide phase hardness, calcium treatment, and inclusion morphology, among others.

MORE INFORMATION

Ask a question or request a quote fulfilling the mask below

or call us at (+39) 0523 881 900

Required fields marked with *

YOU NEED ANOTHER TEST?

SIDERTEST

is ACCREDITED FOR A WIDE RANGE OF TESTS