DROP WEIGHT TEST (DWT Test)

DWT Test determine the nil-ductility transition (NDT) temperature of ferritic steels.

The main reference standard for the DWT is: ASTM E208 Standard Test Method for Conducting Drop-Weight Test to Determine Nil-Ductility Transition Temperature of Ferritic Steels

The DWT Test uses three type of specimens, with a centrally located weld bead, approximately 50 mm long and 12.7 mm wide.

Specimens DWT Test

Type of specimen |

Specimen Size [mm] |

| P1 | 25x89x356 |

| P2 | 19x51x127 |

| P3 | 16x51x127 |

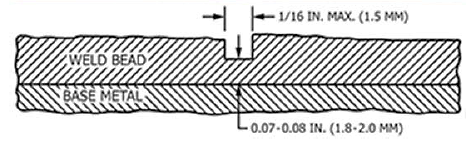

At the center of the weld length is performed a notch which must have a maximum width of 1.5mm and a thickness of the weld from the end of the notch to the surface of the base material between 1.8-2.0mm.

The impact test is carried out by applying an energy dependig on the yield strength of the material to be tested.

DWT Test specimen

Notch size

NDT Temperature determination (Nil Ductility Temperature)

The selection of test temperatures is based on finding, with as few specimens as possible, a lower temperature where the specimen breaks and an upper temperature where it does not break, and then testing at intervals between these temperatures until the temperature limits for break and no-break performance are determined within 5 °C.

The NDT (Nil Ductility Transition) temperature is the highest temperature where a specimen breaks when the test is conducted by this procedure. Test at least two specimens that show no-break performance at a temperature 5 °C above the temperature judged to be the NDT temperature.

After each drop weight test, the specimen shall be examined and the result of the test shall be BREAK or NO BREAK.

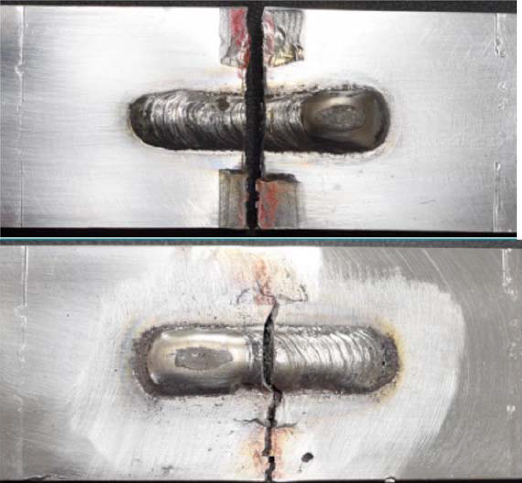

Broken Drop-Weight Specimens (BREAK)

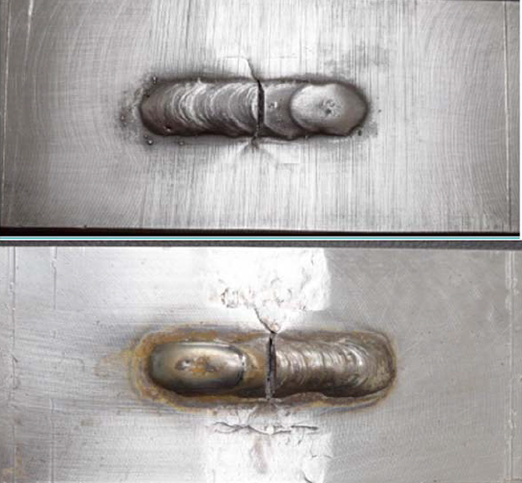

NO BREAK performance in Drop-Weight Specimens

A specimen is considered broken if fractured to one or both edges of the tension surface.

A specimen is considered no broken if develops a visible crack in the crack-starter weld bead that is not propagated to either edge of the tension surface.

A specimen is considered no test if either weld-deposit notch is not visibly cracked after completion of a test, or if the drop-weight specimen is not deflected fully to contact the anvil stop. A No-Test performance may result from the use of insufficient impact energy, the use of a too-ductile weld metal for crack-starter weld bead, or misalignment of the specimen so that the crack-starter weld bead obstructs full deflection to the anvil stop. The No-Test sample shall be discarded and a retest, using another sample, shall be required.

MORE INFORMATION

Ask a question or request a quote fulfilling the mask below

or call us at (+39) 0523 881 900

Required fields marked with *

YOU NEED ANOTHER TEST?

SIDERTEST

is ACCREDITED FOR A WIDE RANGE OF TESTS