CTOD TEST (Crack Tip Opening Displacement)

Determining the critical crack tip opening displacement (CTOD) fracture toughness of metallic materials.

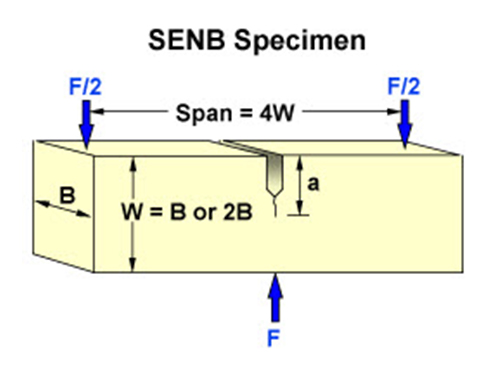

In case of three-point bending is used SENB specimen. The dimensions can be BxB or Bx2B and the minimum length of specimen is 4.6W (B is the thickness and W the width).

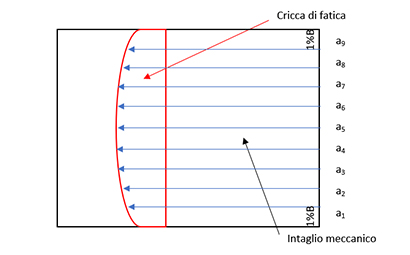

CTOD Testing uses fatigue precracked specimens.

The precracking is necessary to create a “natural crack”.

A fatigue crack shall be developed from the root of the machined notch of the specimen with as acute a notch root radius as possible.

These specimens are tested in displacement controlled monotonic loading at a constant rate of increase in stress intensity factor within the standard range (rate of increase in stress intensity factor is expressed in MPa √m/s) during the initial elastic deformation.

During the CTOD test the force and corresponding displacement measured to the crack tip opening shall be recorded.

The specimens are loaded to fracture or the maximum force associated with plastic collapse.

SENB specimen

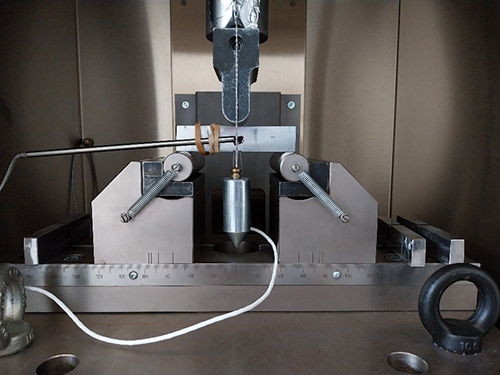

CTOD Test – Fixture for three point bend tests

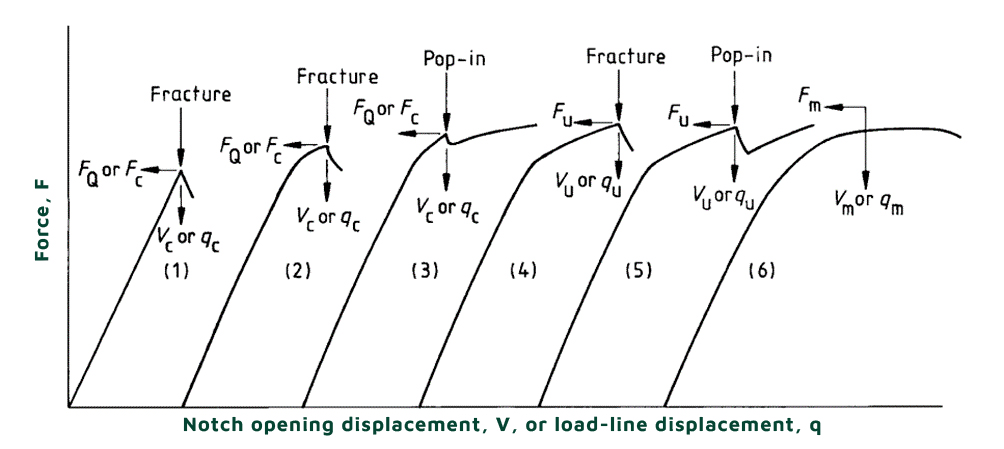

FROM THE CTOD TEST THE FOLLOWING GRAPHS CAN BE OBTAINED:

Characteristic type of force versus displacement records in CTOD test (reference standard BS7448-1:1991)

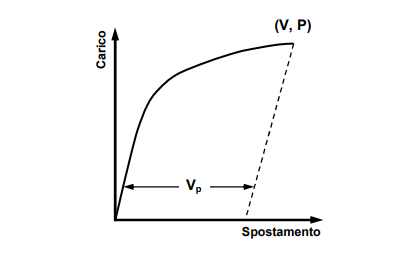

CMOD e fracture toughness

The plastic component of crack-mouth opening displacement Vp corresponding to the crack-mouth opening displacement Vc, Vu, or Vm is determined and recorded

After the test has been completed, the fracture surface of the specimen is examined and measured to determine the original crack length (ao) and the amounts of any stable crack extension (Da).

ao is determined with the following formula:

ao = [(a1+a9)/2 + a2 + a3 + a4 + a5 + a6 + a7 + a8]/8

CTOD value is composed from two components, one elastic (del) and the other plastic (dpl) and is expressed in mm.

If conditions and limits imposed by the standard are respected, the CTOD value obtained is considered valid.

MAIN REFERENCE STANDARDS FOR THE CTOD TEST (CRACK TIP OPENING DISPLACEMENT)

BS 7448-1 Fracture mechanics toughness tests-Method for determination of KIc, critical CTOD and critical J values of metallic materials

BS 7448-2 Fracture mechanics toughness tests-Method for determination of KIc, critical CTOD and critical J values of welds in metallic materials

ISO 12135 Metallic materials – Unified method of test for the determination of quasistatic fracture toughness

ISO 15653 Metallic materials – Method of test for the determination of quasistatic fracture toughness of welds

ASTM E1820 Standard Test Method for Measurement of Fracture Toughness

MORE INFORMATION

Ask a question or request a quote fulfilling the mask below

or call us at (+39) 0523 881 900

Required fields marked with *

YOU NEED ANOTHER TEST?

SIDERTEST

is ACCREDITED FOR A WIDE RANGE OF TESTS