GALLING TESTS

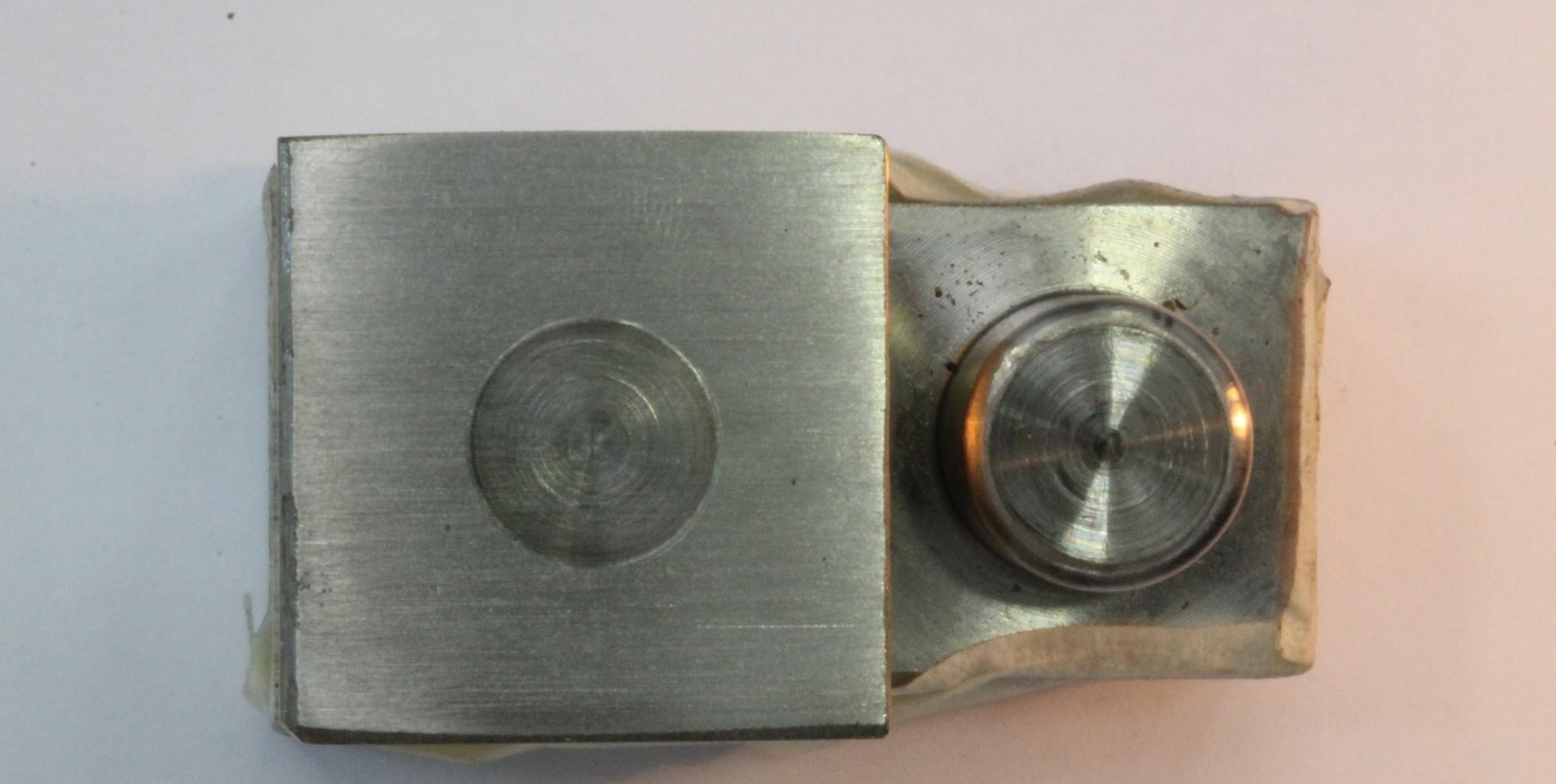

The test requires a couple of specimens to be subjected to a constant, compressive load. One specimen is called the button and is generally rotated about its axis on the other flat specimen called the block. A tool like an open-end wrench may be used to rotate the specimen. After releasing the load, both specimens are examined. If the specimens appear smooth and undamaged to the unaided eye, the procedure shall be repeated at higher load. Burnishing and slight scratch marks is not considered as galling, but torn metal and cold welded areas.

TEST METHODS

- ASTM G98

DESCRIPTION OF THE PHENOMENON

The term galling refers to a form of surface damage arising between sliding solids, distinguished by macroscopic roughening and creation of protrusions above the original surface.

SThe onset of galling usually requires that the contact pressure exceeds some threshold value referred to as threshold galling stress.

MORE INFORMATION

Ask a question or request a quote fulfilling the mask below

or call us at (+39) 0523 881 900

Required fields marked with *

YOU NEED ANOTHER TEST?

SIDERTEST

is ACCREDITED FOR A WIDE RANGE OF TESTS