IDENTIFICATION OF DETRIMENTAL INTERMETALLIC PHASES

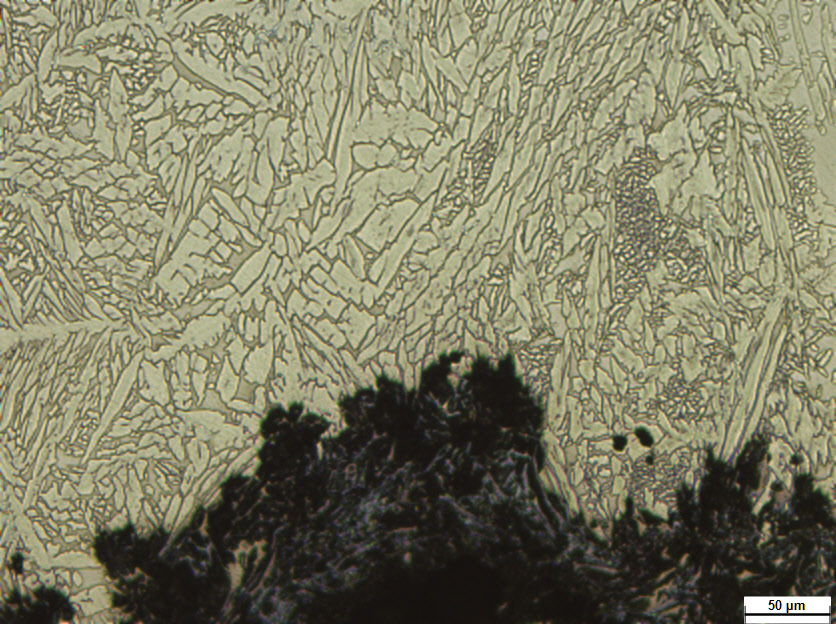

Determination of detrimental intermetallic phases in duplex and superduplex stainless steels shall be performed by method described in ASTM A923 and ASTM A1084. Both of them are structured on three different methods. First one (Method A) is a metallographic evaluation that allow to classify microstructure after an electrolytic etching with sodium hydroxide. Sigma phase appear at grain border between ferrite and austenite. Its presence undermine material mechanical proprieties and also a Charpy impact test can be performed in order to spot it (Method B). Energy absorbed may change as function of sigma phase percentage and reaching the acceptance criteria verify if its presence did not undermine the material mechanical properties.

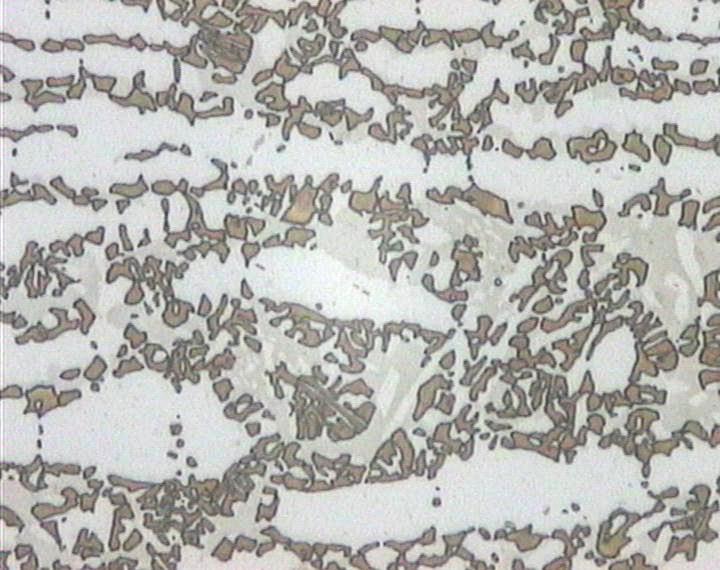

A third test used to evaluate presence of intermetallic phases is a corrosion test (Method C) in ferric chloride analogue to test G48 method A. Test time and temperature change in function of the selected alloy. After cleaning and removal of eventual corrosion product, test sample shall be weighted and this data is used to calculate corrosion rate. This is expressed for ASTM A923 and ASTM A1084 in milligrams per square decimeter or mdd. Both standards give acceptability limits for different type of alloy.

Detrimental intermetallic phases can be performed also in other ways. For example, international standard ISO 17781 is widespread used to qualify duplex alloys for Oil and Gas applications. In this particular case similar test are performed but with different acceptance criteria.

TEST METHODS

- ASTM A 923 – Method A

- ASTM A 923 – Method B

- ASTM A 923 – Method C

- ASTM A 1084 – Method A

- ASTM A 1084 – Method B

- ASTM A 1084 – Method C

PHENOMENOM DESCRIPTION

Among stainless steels biphasic ones (Duplex and Superduplex) are characterized by a particular corrosion resistance in ambient containing chlorides.

Presence of an Austenitic and Ferritic microstructure at the same time and balance at about 50% guarantee a good resistance to localized corrosion and insensibility to intercristalline corrosion maintaining mechanical proprieties similar to Austenitic alloys. Duplex are therefore widely used in the chemical, petrochemical industries and offshore application.

However, this resistance is undermined by the presence of intermetallic phases which can be generated when the material is subjected to temperatures between 300 and 1000°C. While the precipitation of carbides plays a secondary role, it is more frequent to run into the sigma phase which is generated on the ferrite at temperatures between 600 and 1000°C following its decomposition into sigma and austenite phases. Materials not adequately solubilized at high temperature and followed by rapid cooling can show the presence of this phase on the edge of the ferrite.

The sigma phase not only lowers the alloy localized corrosion resistance but also the Joules absorbed during the impact test. The determination of its presence is therefore essential to evaluate that a duplex or superduplex steel has been produced correctly and that it can work in service conditions without showing breakages or noticeable corrosion phenomena.

MORE INFORMATION

Ask a question or request a quote fulfilling the mask below

or call us at (+39) 0523 881 900

Required fields marked with *

YOU NEED ANOTHER TEST?

SIDERTEST

is ACCREDITED FOR A WIDE RANGE OF TESTS